Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

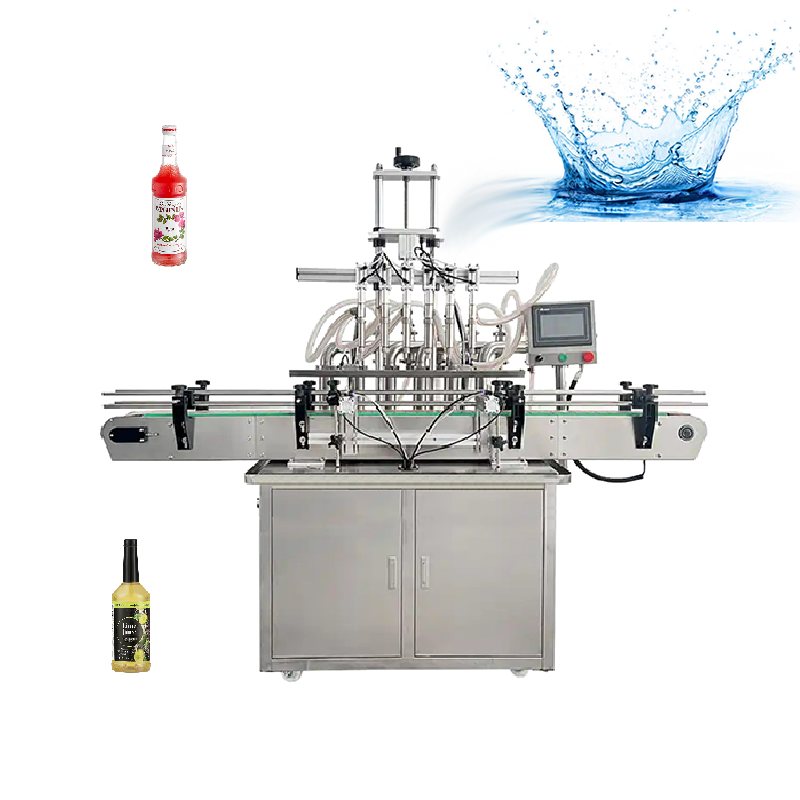

Automatic liquid filling machine

The automatic liquid filling machine is engineered for precise and efficient filling of liquids such as water, wine, milk, edible oil, and flavored drinks. With a customizable measuring range from 20ml to 200ml and a filling speed ranging between 30 to 70 bottles per minute (depending on the volume), it integrates seamlessly into bottling lines. This machine, equipped with 2 to 12 filling heads, operates with a power rating of 2KW at 220V, ensuring reliability and versatility in liquid packaging processes.

Automatic Liquid Filling Machine

Product Description

The JK-LF6 automatic liquid filling machine is designed for efficient and precise liquid filling operations. With a customizable measuring range of 20-200ml and a filling speed ranging from 30 to 70 bottles per minute, it caters to various liquids such as water, wine, milk, edible oil, and vinegar products. Featuring a compact size of 2200x1400x1600mm and weighing 300kg, it supports integration with capping and labeling machines in a bottling line setup, offering complete automation and intelligent control capabilities.

Product Specification

| Model | JK-LF6 |

| Filling Speed | 30-70 bottles/min (depend on filling volume) |

| Measuring Range | 20-200ml Customized |

| Power | 2KW,220V,50HZ |

| Barometric | 0.4-0.6MPa |

| Machine Size(L*W*H) | 2200*1400*1600mm |

| Machine Weight | 300kg |

| *Number of filling heads*2.4.6.8.10.12 (customizable) | |

Product Features

High Filling Speed: Capable of filling 30-70 bottles per minute (depending on the filling volume), ensuring efficient production rates.

Customizable Measuring Range: Supports a measuring range from 20ml to 200ml, adaptable to various liquid volumes and product requirements.

Versatile Application: Suitable for filling various liquids including water, wine, milk, edible oil, flavored drinks, and vinegar, accommodating diverse production needs.

Flexible Number of Filling Heads: Available with 2, 4, 6, 8, 10, or 12 filling heads (customizable), allowing for scalable production capacity based on specific requirements.

Product Advantages

Reduced Product Contamination through Closed Systems and Sanitary Design: Automatic liquid filling machines are equipped with closed systems and sanitary design features such as stainless steel construction and sealed filling chambers. These features minimize the risk of contamination from external elements like dust, particles, or microorganisms. By maintaining a hygienic environment throughout the filling process, the machine ensures the integrity and safety of the product.

Reliable Performance with High-Quality Components and Longevity: Automatic liquid filling machines are constructed using high-quality materials such as stainless steel and robust components like servo motors and PLC control systems. This robust build ensures durability and reliability, enabling the machine to perform consistently over extended periods without frequent breakdowns or maintenance issues.